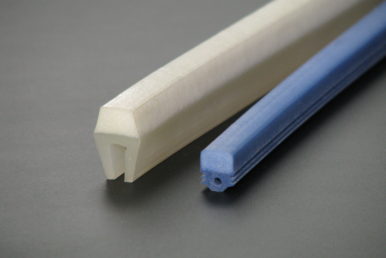

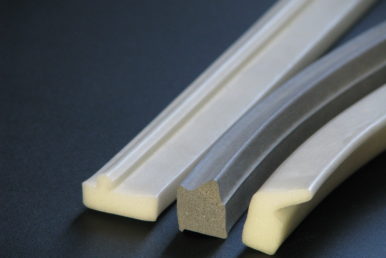

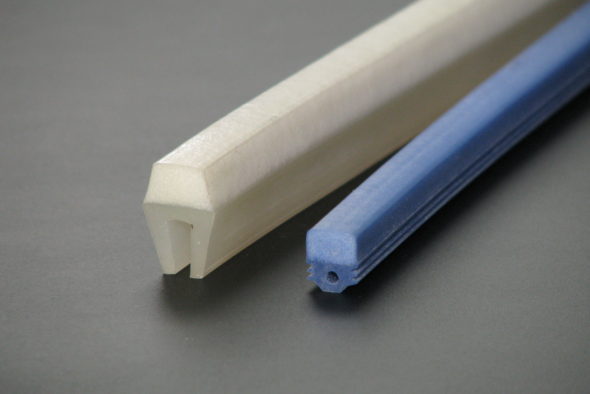

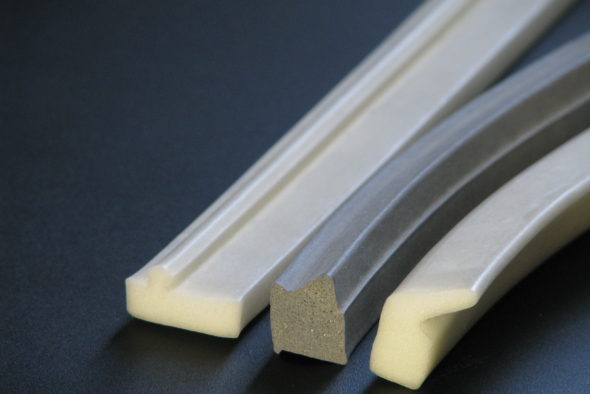

Silex realizes silicone profiles according to your specifications up to 200 mm in width and 50 mm in height.

Because our compounds are produced in-house, we can set the physical and chemical properties of the profiles individually. In terms of designs, the profiles range from simple round cords and square profiles to very complex profiles with the smallest possible tolerances for very high requirements.

Silex processes standard silicone rubbers (MVQ) with Shore A hardnesses from about 10 to 90 as well as special silicone rubbers for low temperature applications (PMVQ) and fluorosilicone rubbers (FMVQ) for applications where there is contact with gasolines, oils, and organic solvents.

GENERAL PROPERTIES

- Excellent resistance to hot air (special compounds up to 300°C).

- Very good UV, ozone, and weather resistance (without anti-aging agents).

- Good chemical resistance.

- Almost unchanged physical properties over a wide range of temperatures (-45°C to 180°C).

SPECIAL FEATURES

- Electrically conductive.

- Design and manufacturing of silicone coextrusion profiles in which 2 different types of silicone are realized in a single profile.

- Integration of threads to prevent stretching and allow “elongation-free” assembly.

- Application of self-adhesive tapes as assembly aids.

- Lowering of the coefficient of friction by modifying the surface (less dull rubber).

- Can be glued or vulcanized together to form rings or frames.

- Delivery of cut or stamped sections.

- Labeling (printer / laser).

The profiles are generally packaged according to your specifications and needs. The standard packaging format is a loose roll or wound on reels.